Industrial Products

Industrial Filtration Systems

Yardney offers a complete line of filtration systems for industrial and commercial applications. Since 1965, Yardney filters have been used across a broad spectrum of industries to meet the challenges of varied and demanding water quality standards. It’s filtration technology that works.

The Yardney industrial product line includes three distinctly different types of backwashing media filters, including the technologies of Sand Media, Multi-Media and Granular Activated Carbon. Other media selections, such as organic clay, zeolites, iron, manganese and arsenic are available for special applications, in addition to Green Sand and Green Sand Plus. Through the proper selection and customization, Yardney can assist with the best suited filter for your specific application.

While our products have continued to evolve and improve, the same basic principles of design are in practice today. With filter technology that has been tested in hundreds of applications, thousands of times over—we know what works.

Sand Media Filters

Automatic or Semi-Automatic

Deep Bed Sand Media Filters

Automatic or Semi-Automatic

Yardney Industrial Sand Media Filters are designed for the most challenging dirty water conditions with a high performance solution for water filtration down to 20 microns. These durable carbon steel filters utilize a 24″ sand media bed for removal of organic and inorganic suspended solids for filtering large volumes of water with very little pressure drop and a long-term value. All Yardney industrial media filters utilize our simple backwash system for ease of operation and consistent water quality. The Yardney automatically controlled filter systems operate for extended periods of time prior to a short backwash cycle.

Yardney Deep Bed Sand Media Filters are designed for the most challenging dirty water conditions with a high performance solution for water filtration down to 15 microns. These durable carbon steel filters utilize a 36″ sand media bed for removal of organic and inorganic suspended solids for filtering large volumes of water with very little pressure drop and a long-term value. All Yardney industrial media filters utilize our simple backwash system for ease of operation and consistent water quality.

Mini-Media Filters

Multi-Media (MM) Filters

Automatic or Semi-Automatic

Yardney Mini-Media Filters are designed as a sand media solution for lower-flow applications. These rugged, simple filters are built with the same high performance and high efficiency standards as our other product lines. Constructed of high strength carbon steel, the Mini-Media is fusion epoxy lined on wetted surfaces. Underdrains are made of Type 304 stainless steel for extra-long life.

Yardney Multi-Media Filters are designed for enhanced water quality filtration for the removal of organic and inorganic suspended solids down to 5 microns. Multi-Media filters may be used as a stand-alone system or in conjunction with or as a pretreatment for other filtration technologies. The Multi-Media filtration systems utilize a vertical side shell depth of 60″ with accompanied reverse stacked medias for progressive filtration through the filtration system. All Yardney industrial media filters utilize our simple backwash system for ease of operation and consistent water quality.

Recirculating Water (RCW) Systems

Manual or Automatic Clean Systems

Granular Activated Carbon (GAC) Filtration Systems

Automatic or Semi-Automatic

Yardney RCW (Recirculating Water) Systems are designed specifically for the filtration and removal of suspended solids from recycled cooling tower or plant process water. Suspended solid contaminants in the cooling tower system significantly reduce heat transfer capability and increase plant operating costs. The Yardney RCW system offers a high performance solution for filtration down to 15 microns and utilizes our simple backwash system for ease of operation and consistent water quality.

Applicable products for RCW Systems include:

Yardney Granular Activated Carbon (GAC) Filtration Systems use the adsorptive qualities of the media to remove highly dispersed compounds from water sources too small for the removal with standard multi-media filtration technology. These automatic filtration systems are extremely effective in removing chlorine and chlorine related compounds, organic chemicals, tastes and odors, halogenated organic compounds, hydrocarbons and other highly dispersed contaminants. Yardney GAC filtration systems utilize a vertical side shell depth of 72 inches. All Yardney industrial media filters utilize our simple backwash system for ease of operation and consistent water quality. The Yardney automatically controlled filter systems operate for extended periods of time prior to a short backwash cycle.

Large Vessels

Maxi-Flush (MFS) Screen Filters

Manual or Automatic Clean

Yardney Large Vessels are manufactured up to 144″ in diameter in both ASME Code and Non Code construction. Available in Carbon Steel or Stainless Steel and designed engineered and manufactured to your specifications. Applications within the water industry include Sand Media, Multi-Media, GAC, PFAS, PFOS, PFOA, in addition to air receivers, surge suppression, liquid or chemical storage and beyond.

Yardney Maxi-Flush Automatic Backwash Screen Filters provide the ultimate in high-rate screen filter performance. Built for durable trouble-free service, the filter and cartridge have no internal moving parts to wear out, break down or replace. The field changeable stainless steel filter cartridge requires no maintenance and is constructed with burst strength in excess of 400 psi.

Thru-Flush Screen Filters

Yardney-Filtaworx (FW) Automatic Self-Cleaning Screen Filters

Yardney Thru-Flush Screen Filters provide excellent filtration for water sources where inorganic particulate is the major contaminant. The Thru-Flush cleaning action quickly purges the trapped contaminant from the filter using your source water line and pressure. This technology utilizes turbulent water action to shake loose the contaminant from the screen and discharge the contaminant out of the housing.

Yardney-Filtaworx Automatic Self-Cleaning Screen Filters provide excellent protection for all types of irrigation systems, including drip, micro-spray, sprinklers and golf course systems. Filtaworx screen filters are one of the most technically innovative self-cleaning filters available, combining proven high performance, reliability and economy in a compact robust design.

Basket Strainers (SB) – Manual Clean

Spin Flow (SF) Screen Filters – Manual Clean

Yardney Basket Strainers are a low-cost filter solution designed to be used for the removal of inorganic contaminants. Basket strainers trap gross contaminants and are able to withstand a substantial amount of loading without failure. When used as a secondary filter, the basket strainer is intended to capture contaminants that may enter the system as a result of a pipeline break or system malfunction.

Yardney Spin Flow Screen Filters offer the benefits of a vortex action spin flow with the advantages of a woven mesh screen filter. Water enters the screen housing tangentially, vortexing the flow—a technique that separates heavy particulate away from the fine mesh cartridge. This method of separation simplifies and reduces cartridge cleaning. Heavy sediment is flushed from the filter through a conveniently located flush port, while the finer contaminant is trapped on the fine screen cartridge.

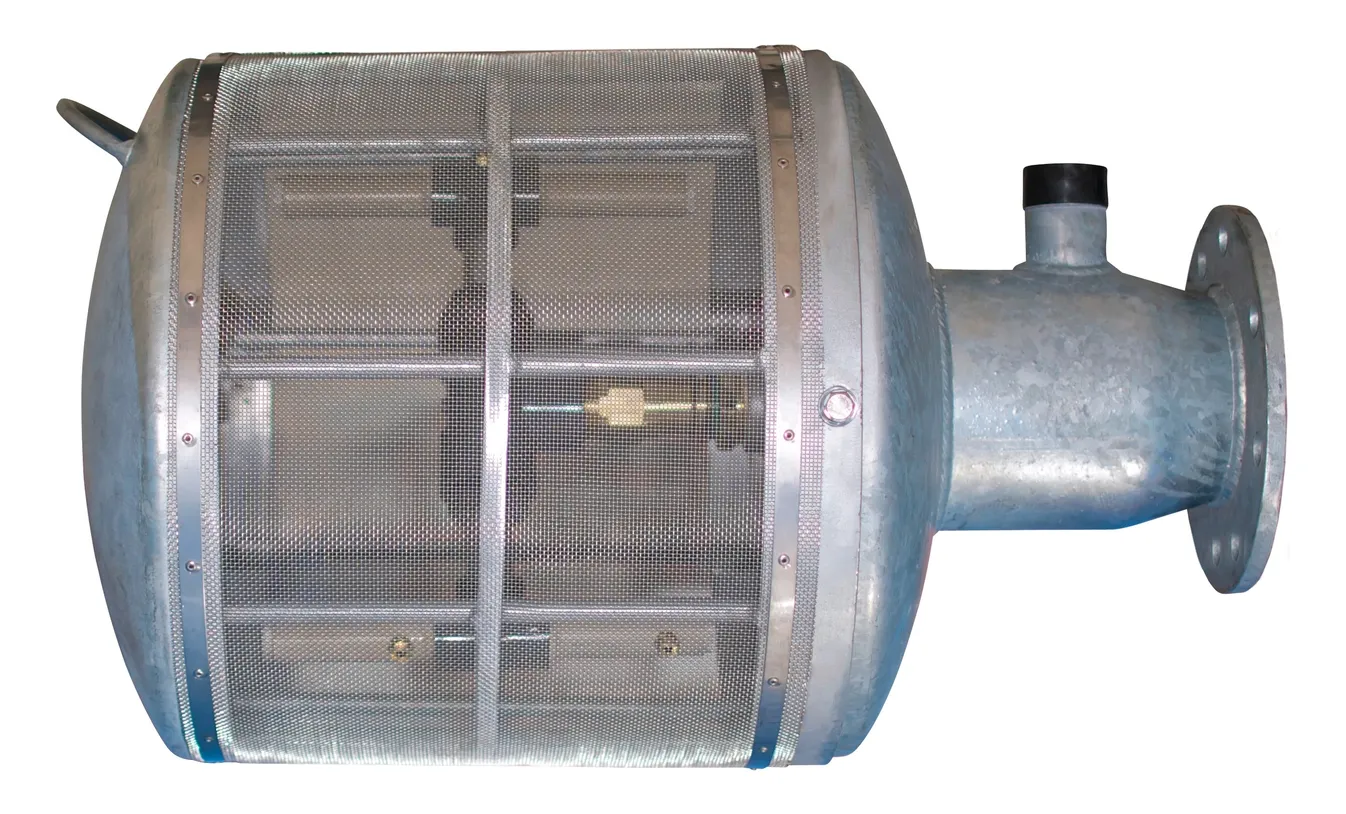

Pump Suction Screen – Automatic Clean

Galvanized Check Valves

Yardney Pump Suction Screens are designed to filter larger, heavier contaminants on the pump intake piping to allow other equipment further down the infrastructure, such as pumps or primary filtration units, to run smoothly without clogging or blinding. Our self-cleaning screens are designed to continuously remove trash and debris from water sources, saving you time, fuel and maintenance costs. Pump suction screens can be used for agricultural, turf, industrial, centrifugal or turbine pump applications.

Yardney’s Galvanized Check Valves are highly recommended for use on pump inlets for retaining system pressure. These may be used with or without a Yardney pump suction screen, and also include a 3/4″ fitting to drain the system for maintenance or winterizing.

Centrifugal Sand Separators

Backwash Valves

Yardney Centrifugal Sand Separators are ideal for removal of suspended solids and inorganic materials with a specific gravity of 2 or greater. This highly effective system will provide consistent, simple removal of inorganic material down to 75 microns. Easily installed, these carbon steel units are rated to 150 psi with threaded or flanged inlet and outlet connections. Smaller models are designed for vertical installation while larger models are angled and floor or ground mounted.

Sizing must be within the specified flow range for proper centrifugal action. Larger flow separators and custom designed systems are available.

Yardney Backwash Valves are manufactured in-house. All three Yardney backwash valve models (1-1/2″, 3″ & 4″) are manufactured from cast iron and CNC machined for proper and effective sealing of all wetted surfaces in order to achieve the lowest documented pressure drop in the industry. The Yardney Backwash Valve is designed as standard equipment to be 100% field serviceable with basic hand tools and includes a grease fitting for valve shaft lubrication and replaceable brass bushing and all sealing and gasketed surfaces.

Specialty Medias

Yardney Water Filtration Systems can include Specialty Medias with our filtration systems or as a stand alone media. In either case, we can tailor the media to a specific water quality, including crushed glass, Green Sand and Green Sand Plus, IMA-65 and others for addressing water quality problems such as iron, manganese, arsenic, hydrogen sulfide and radium from your water source.

Applicable products for RCW Systems include:

- Ion Exchange (IX) Resin

- Granular Activated Carbon (GAC)

- Green Sand Plus

- IMA-65

- Crushed Glass

- Organoclay